|

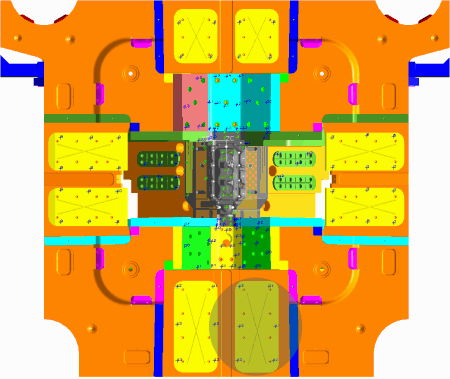

Engine Block Die Assembly

|

|

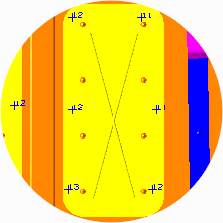

Units - 0.001" green - in tolerance red - missing material blue - extra stock |

|

| The Part: | Engine Block Die Massive and complex casting tool for an aluminum V6 engine block. |

| The Process: | Ware Plate Fitting The ware plates are manufactured with approximately 0.010" of stock before fitting. The two die halves are assembled and brought to inspection. The task is to find how much stock actually is on each ware plate in die position. At the end, the ware plates will be taken off the exact amount of stock needed. |

| The Results: | To check the ware plates from 2D drawings previously took 2-3 days. With SPV it takes under 3 hours - 2 hrs to collect the points at the CMM, 20 min to check the points with SPV at the CAD station and 30 min to generate plots displaying the measured results. This process also included a limited check (200 points) on the insert in the middle which was never inspected before at this stage. |

| Highlights: | In this example 650 points were checked against 12,000 faces in less than 10 seconds on SUN Ultra 30 with 512 Mb of memory |

Sitius Inc., Copyright 1998-2015